Description

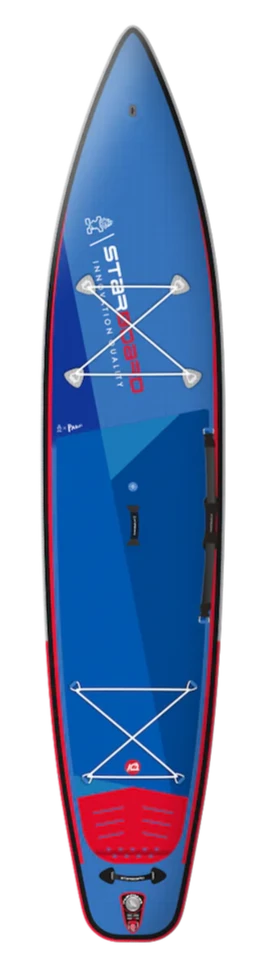

023 STARBOARD 14’0”x25.5” SPRINT

RECYCLED PLASTIC BOTTLES

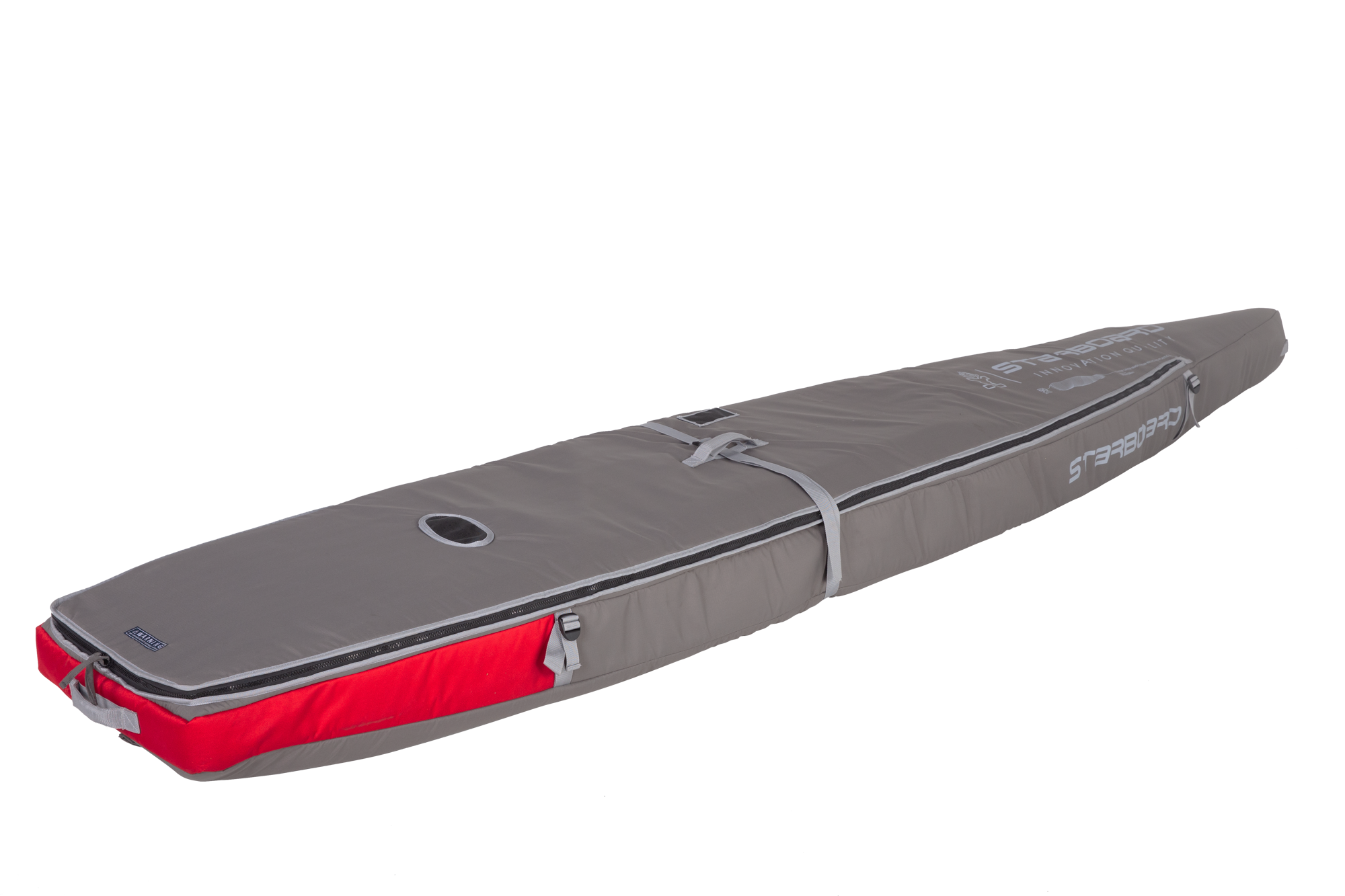

The outer layers of the SUP & paddle bags are made with ultra-resistant 450D anti-tear fabrics, made from recycled plastic bottles, in partnership with “Waste2Wear.r”. The bottles are first cut into flakes, washed, melted and extruded into threads with which they make the fabric.

It takes between 30 and 150 bottles to make a SUP cover. All these bottles then end up back on the market and in a different form, without any further risk of pollution for our environment.

Ripstop weaving technology provides very high resistance to wear and tear.

REVERSE MANUFACTURING

Our Starboard covers made from recycled materials are made inside out and then turned inside out, like t-shirts. This manufacturing method allows for lighter covers, but with a double layer of protection all around the rails, all along the seams.

This reverse manufacturing avoids the addition of additional reinforcements, for the benefit of greater lightness.

YKK NON-CORROSIVE ZIPPERS

High quality, non-corrosive YKK buckles and zippers are positioned around the periphery of the cover, far enough away from the rails to avoid any risk of damaging them, while removing the need for additional protective inner layers.

This helps to further reduce the weight of the cover.

A travel bag is also ideal for storing your board when not in use, providing extra protection from UV rays, weather and the inevitable knocks and bumps.

STARBOARD'S 10 X CLIMATE POSITIVE ENVIRONMENTAL INITIATIVE:

For every tonne of CO2 emitted during the manufacturing of our bags and accessories, we plant 3 mangrove trees with Worldview International Foundation.

Each Mighty Mangrove absorbs 673 kg of VCS certified CO2 over its first 25 years.

Together, our mangroves offset emissions 10 times over and help fund livelihood projects in Myanmar.

You may also like

Recently viewed