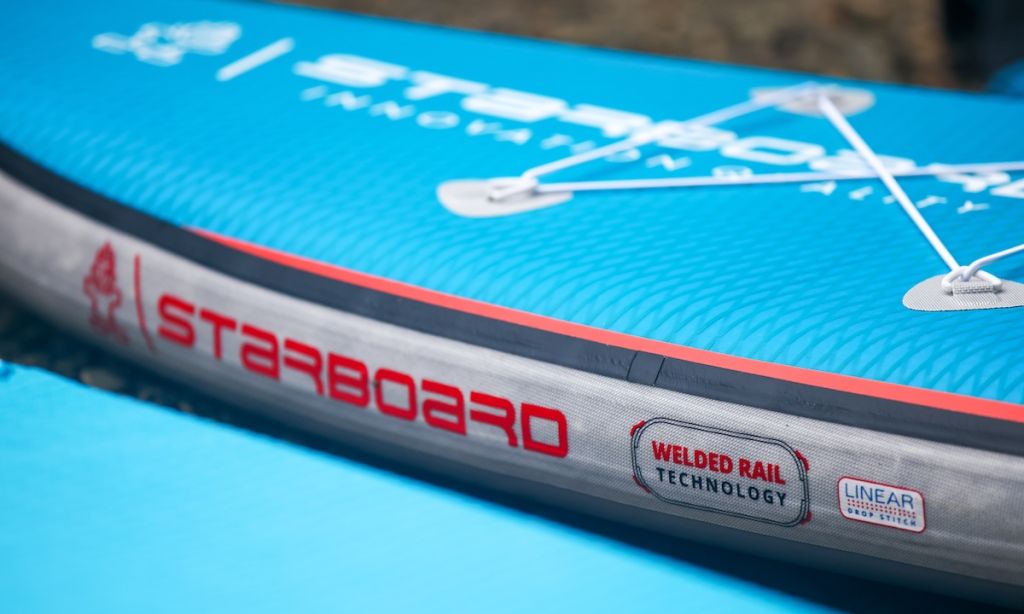

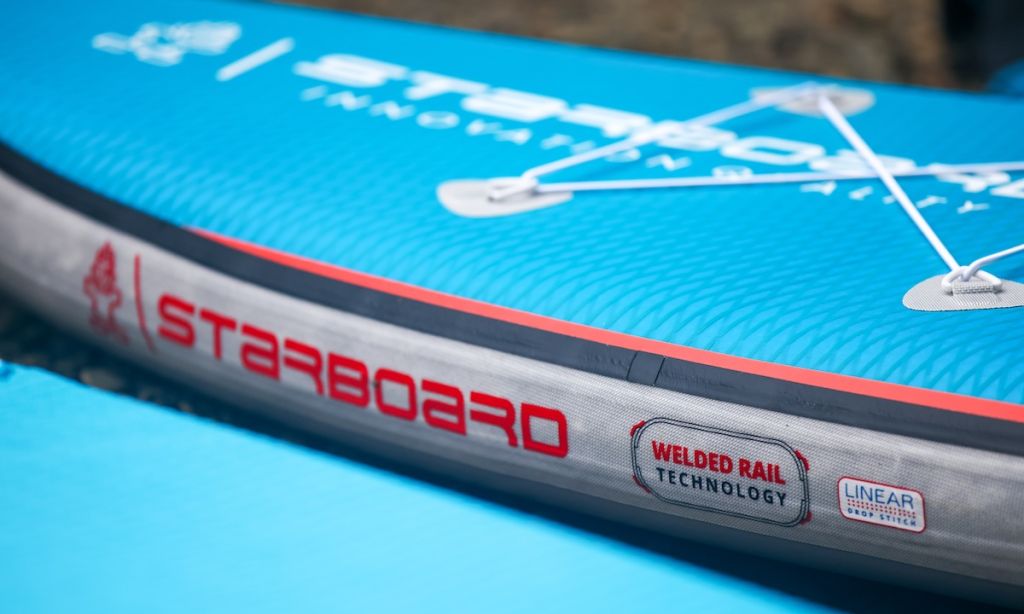

Inflatable stand-up paddleboards (SUPs) have revolutionized water sports, combining the thrill of surfing with the ease of paddling across calm waters. Among the leading innovators in this industry is Starboard, a company renowned for enhancing the durability and performance of inflatable SUPs through their pioneering welded rail technology. In this guide, we'll explore how this technology works and why it's a game-changer for paddleboarding enthusiasts.

Introduction

Have you ever wondered why some inflatable SUPs last longer and perform better than others? The secret often lies not just in the materials used, but also in how they are constructed. Starboard has been at the forefront of this innovation with their welded rail technology. Let’s dive into how this technology is setting new standards in the SUP industry.

Understanding SUPs and Starboard's Market Presence

Starboard, a titan in the water sports industry, has consistently pushed the boundaries of what's possible with inflatable SUPs. Known for their robust construction and innovative designs, Starboard SUPs are a favorite among both beginners and seasoned paddlers.

What is Welded Rail Technology?

Welded rail technology involves the fusion of the top and bottom layers of the SUP along the sides using advanced welding techniques. This method replaces traditional glue, offering a stronger, more reliable bond.

Benefits of Welded Rail Technology

Welded rail technology represents a significant advancement in inflatable SUP design, primarily because it addresses the common vulnerabilities found in traditional inflatable boards.

The most fundamental advantage of welded rail technology is the superior structural integrity it provides. By thermally bonding the seams of the SUP, the board becomes a single cohesive unit, which significantly enhances its strength and resilience against physical stresses.

Leaks and air loss can be an issue with glued seams, particularly as the adhesive ages and degrades. Welded seams, in contrast, form an airtight seal that maintains consistent air pressure within the board, ensuring optimal performance and reducing the frequency of reinflation.

Welded seams are remarkably durable. They are resistant to peeling, cracking, or weakening that often plagues glued seams exposed to sun, salt, and frequent use. This durability extends the life of the board, making it a more sustainable investment for avid paddlers.

Beyond functionality, welded rails provide a sleeker, more polished look compared to the often bulky appearance of glued seams. This aesthetic appeal is significant for users who value the visual aspect of their sports equipment.

Enhanced Performance on the Water

The most immediate benefit of welded rail technology that paddlers notice is the enhanced performance on the water. The rigidity provided by welded seams closely mimics the feel of a traditional hardboard, offering superior control and stability. This makes turning and maneuvering easier, which is especially beneficial in choppy waters or when navigating around obstacles.

|

|

Durability and Longevity

The durability and longevity of Starboard’s inflatable SUPs are greatly enhanced by their welded rail technology, with several key aspects contributing to their robust performance:

- Resistance to Elements: The welded construction offers excellent resistance to environmental factors such as UV rays, salt water, and extreme temperatures, which are known to deteriorate traditional glued seams over time.

- Less Vulnerable to Damage: The seamless bond created by welded technology is less susceptible to physical damage. Whether it’s accidental drops, collisions, or rough handling during transport, welded seams are more likely to maintain their integrity compared to their glued counterparts.

- Long-term Reliability: With a lower likelihood of seam failure, welded rail SUPs provide paddlers with a reliable platform for their activities, ensuring consistent performance over years of use. This reliability is particularly valued in environments where equipment failure can compromise safety.

- Minimal Maintenance Required: The robust nature of welded seams reduces the need for frequent maintenance checks and repairs, saving users time and money. This aspect is particularly appealing to those who use their SUPs intensively or in remote locations where repair options are limited.

- Enhanced Resale Value: Due to their extended lifespan and maintained condition, welded rail SUPs often retain a higher resale value compared to traditional boards. This is an important consideration for users who frequently upgrade their gear or wish to recoup part of their investment in the future.

Eco-Friendly Innovations

Starboard is committed to sustainability, and their welded rail technology reflects this ethos. By eliminating the need for adhesives, welded rails reduce the environmental impact associated with SUP manufacturing. This process not only lowers the carbon footprint but also decreases the potential for environmental degradation during the board's lifecycle. Furthermore, the durability of welded rails means fewer SUPs are discarded due to wear and tear, promoting a more sustainable approach to paddleboarding.

Comparison with Traditional Glued Rails

Compared to traditional glued rails, welded rails offer significant advantages. Glued seams can degrade over time, especially when exposed to extreme temperatures or sunlight, leading to air leaks and structural failures. In contrast, welded seams are more resistant to such elements, maintaining their integrity over a longer period. This not only ensures safety and reliability but also enhances the board's overall performance by maintaining air pressure consistency, which is essential for optimal rigidity and stability.

Maintenance Tips for Your Inflatable SUP

Maintaining a welded rail SUP involves routine checks and basic care. Regularly inspect the board for any signs of wear, especially after use in harsh conditions. It’s important to clean your SUP with fresh water after each use, particularly if used in saltwater, to prevent salt buildup that can degrade materials over time. Store the board in a cool, dry place out of direct sunlight to protect it from UV damage.

Cost-Effectiveness

Initially, some of Starboard’s welded rail SUPs might seem more expensive than traditional glued options. However, considering the longer lifespan, reduced need for repairs, and better performance, the overall cost-effectiveness is clear. These boards are an investment in quality and durability, offering paddlers a product that will perform well and last longer, thereby saving money in the long term on replacements and repairs.

Where to Buy Starboard SUPs

Starboard SUPs are available through various channels. You can purchase them directly from Starboard's official website. Additionally, many sports equipment stores and specialty water sports outlets carry Starboard products. Find a Starboard shop here.

Future of Inflatable SUP Technology

The future looks bright for inflatable SUP technology, with ongoing advancements aimed at enhancing performance, durability, and environmental sustainability. Starboard continues to innovate, with research focused on even lighter and more durable materials, and on improving the efficiency of their welding techniques. The goal is to create SUPs that are not only easier to transport and store but also perform closer to their rigid counterparts, making them the ideal choice for paddlers of all skill levels.

Conclusion

Starboard's welded rail technology is transforming the world of inflatable SUPs by providing boards that are durable, environmentally friendly, and perform exceptionally on the water. Whether you are a novice looking to try paddleboarding for the first time or an experienced paddler seeking a high-performance board, Starboard offers products that meet a wide range of needs and preferences. With their commitment to innovation and quality, Starboard's SUPs are an excellent investment for anyone passionate about water sports.

FAQs

What makes welded rail technology better than glued rails?

Welded rails provide a stronger, more durable bond that significantly enhances the lifespan and performance of SUPs.

Can welded rail SUPs be repaired if they get damaged?

Yes, though they are less likely to suffer damage, repairs can still be done professionally to maintain integrity.

Are welded rail SUPs worth the extra cost?

Absolutely, considering their increased durability, performance, and eco-friendliness, they offer great value for money.

How long do welded rail SUPs last compared to traditional SUPs?

With proper care, welded rail SUPs can last several years longer than traditional glued models.

Where can I learn more about Starboard and their technology?

Visit Starboard’s official website or contact local dealers to learn more about their technology and products.